Updates on Previous Posts

If you've been reading the posted comments you know that

Jason Wenig of The Creative Workshop in Dania Beach, Florida (

www.thecreativeworkshop.com) contacted me after reading the

Keeping Cool post because the Ghia Aigle he is restoring for the Pebble Beach Concours was also missing its radiator shutter linkage. I sent him my parts so he could copy them and in exchange he will send me a radiator thermostat "widget" so I can replace the faulty one I have. Win-win for all! Both Jason and I are now beneficiaries of

Ed Leerdam's generosity and trust when he loaned me his original linkage for duplication many years ago. Thanks, Ed!

After reading the

39 . . . or 41 . . ? post,

Peter Marshall wrote with very interesting updated information about the Alfatross' siblings which I will pass along in a future post.

Matteo Bosisio of Ruote Borrani, the source for my knock-off hubs mentioned in the

Wheels and Spinners post, sent me addresses for knowledgeable people in both the Zagato and Alfa Romeo companies. I will be making contact with them shortly in the hope that they can answer some persistent questions.

So I don't know how this blog is working for you, but for me it's becoming indispensable!

"Partifacts"

Why does a restoration take so long? I am continually impressed with how well a career in marine archaeology has prepared me for restoration of the Alfatross. Not only am I already accustomed to long hours spent in the tedious, repetitive, and seemingly endless task of cleaning and recording thousands of artifacts, but also familiar with the principle that unless you finish the job, there are no rewards!

|

Archaeologists used small pneumatic chisels to clean the thousands of artifacts

from the Molasses Reef Wreck, the oldest shipwreck found in the Americas.

|

All the basic objectives and procedures are the same whether you are excavating a shipwreck site or restoring an old car. In both cases you are dealing with thousands of individual "partifacts" made of different materials in different stages of deterioration that have to be put back together again.

|

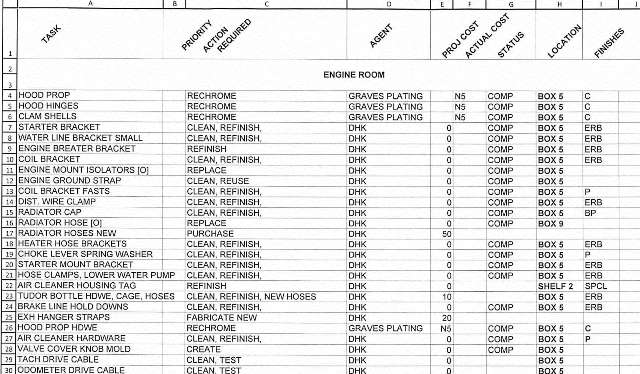

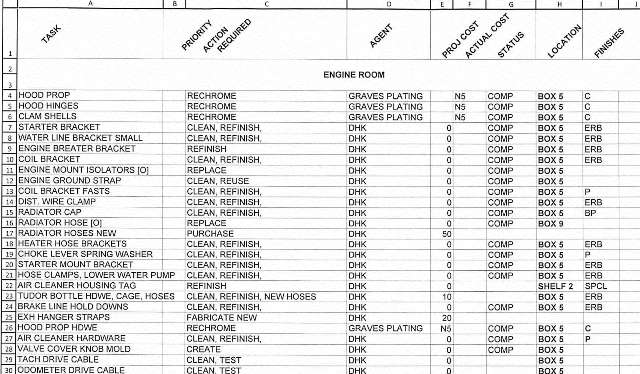

| A few line items from my spreadsheet designed to keep track the Alfatross' "partifacts": |

The Alfatross is made up of more than a thousand individual parts, each one of which has its own special identity and task to perform. Because each piece has to be cleaned, inspected, repaired, checked to make sure it works properly, and refinished, they all go in different directions for various types of treatment before being finally reunited and reassembled. Not surprisingly, no one can remember how all 1,000 pieces go back together, so if you don't use some kind of tracking system things can get out of control in a hurry.

|

What is it? Where did it come from? How do we know where

it goes after it is cleaned, inspected and checked?

Take this simple screw, for example. It is one of about 100 parts that make up the double wishbone left front suspension. I wouldn't remember that now because I took it apart about 10 years ago IF it weren't for the fact that I put every part in a Ziploc bag and labelled where it came from.

The next step was to photograph the artifact--oops, I mean part--on background paper printed with a grid of 1-inch squares to give some idea of scale.

|

|

The Alfatross' left front leg. The screw above goes into the

middle of the spindle (cylindrical shape the axle is attached to)

So now we can actually start to work with the part because we have a record of its identity and where it came from. This one needs degreasing, so the first stop is a nice relaxing solvent bath in the heated, sonic degreaser.

. . . Followed by 24 hours in a vibratory tumbler filled with abrasive pyramids to take off corrosion and whatever else shouldn't be there. . .

. . . Followed by manual scrubbing with Scotchbrite pads under running water to get the abrasive off . . .

. . . Followed by another tour of duty in another vibratory tumbler, this time filled with corn cob granules, to give it a good as new shine (usually).

|

|

This old laboratory sonic cleaner cleaned a lot of marine artifacts

before it took on a grease-heavy diet of filthy Alfatross parts. |

|

Vibratory tumblers one, two, and three (wish I had about 3 more)!

Of course it would take forever to treat each part separately--but if you mix them together to speed up the process won't their identities get mixed up too? No, because the labelled bags and photo IDs follow each piece through the entire process.

Maintaining the spreadsheet takes a lot of time because when you move a part from one stage in the restoration process to the next, you have to update its status on the spreadsheet. But I've had plenty of practice here, too. Each artifact in one of our shipwreck sites has its own entry in a tracking system, and that information follows its conservation/restoration progress through to completion. The artifact database stays with the actual artifact collection forever so that it can be consulted if problems arise in the future.

If this sounds like a lot of work, pity the poor marine archaeologist who might have to do the same things for hundreds of thousands of objects from a shipwreck!

|