Following up the last post about The Alfatross' drum brakes, which was already longer than it should have been, there are still some observations I need to make and a lingering, pestering question I need to pose.

The Alfatross was built the same year that modern hydraulic disc brakes began to appear on production European cars such as the Citroen DS, but it took another decade before 4-wheel disc brakes appeared on production cars in the US. That said, the brakes on The Alfatross exemplify a high degree of refinement of drum brake technology. All four drums are made of cast and machined aluminum with steel liners, reducing unsprung weight. All drums are finned to increase surface area and improve cooling. The fins on the rear drums are cast parallel to the direction of wheel travel while the front drums are cut diagonally to the direction. Under speed, scoops on the backing plates of the front brakes force air across the fins to further maximize cooling and reduce brake fade.

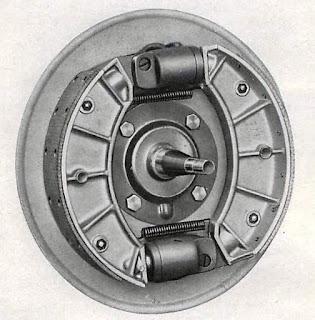

Inside the drums, the shoes are aluminum, again to reduce unsprung weight. The front brakes are equipped with two wheel cylinders per wheel to better handle the stronger forces, while only one cylinder is sufficient for the rears.

One concession to modernity necessary during The Alfatross' restoration was the replacement of its original brake liners with asbestos-free liners chemically bonded to their shoes instead of being riveted as were the originals.

Drum brakes vs. disc brakes

An historian of automotive history might ask why manufacturers and even racers kept making and using drum brakes long after disc brakes had been invented and proven in battle. As a person who owns cars with both types of brakes I can say with certainty that discs do a much better job of stopping, and as a mechanic who works on both types I can't understand why drum brakes were ever used on cars in the first place. After all, the first appearance of disc brakes on a production motor vehicle was in 1902! |

| The Alfatross' finned aluminum brake drums. Note the air scoop attached to the backing plate at left. |

|

| The front drums, which are enormous, do most of the braking and completely fill the space inside the wheel rims. |

The Alfatross was built the same year that modern hydraulic disc brakes began to appear on production European cars such as the Citroen DS, but it took another decade before 4-wheel disc brakes appeared on production cars in the US. That said, the brakes on The Alfatross exemplify a high degree of refinement of drum brake technology. All four drums are made of cast and machined aluminum with steel liners, reducing unsprung weight. All drums are finned to increase surface area and improve cooling. The fins on the rear drums are cast parallel to the direction of wheel travel while the front drums are cut diagonally to the direction. Under speed, scoops on the backing plates of the front brakes force air across the fins to further maximize cooling and reduce brake fade.

|

| Front brake shoes from the Alfa factory repair manual. Note the two wheel cylinders, location of the liners on their shoes, and how the liners are attached to their shoes by rivets. |

One concession to modernity necessary during The Alfatross' restoration was the replacement of its original brake liners with asbestos-free liners chemically bonded to their shoes instead of being riveted as were the originals.

|

| Right rear brake shoes from the factory repair manual. Note the the liners are offset on their shoes. |

|

| One of Dan Allen's shoes fitted with the thicker 1/4in (6.4mm) lining (above) and the thinner 3/16in (4.8mm) lining more in keeping with the originals. |

Rear Brake Liner Mystery

As reported previously, The Alfatross has been plagued by a mysterious problem that rendered the rear brakes ineffectual. One of the suggested causes was brake shoe linings that were too thin or drums that were too worn. Measuring the inside diameter of the drums revealed they are well within specification, so that eliminated them from suspicion.To test the "linings too thin" theory Dan Allen had four of his spare shoes re-lined with thicker material and sent to me. I thought "Now this will surely be the cure!". Much to my dismay, the extra 1/16in of lining prevented the drums from fitting over the shoes! Now we know the thinner linings are not the problem. Not that it matters any more, because at this point I am hopeful that the rear brake problem was solved during the process described in the previous post (# 127)--but I won't know for sure until I put the whole system back together and test it.

The lingering mystery that no one has been able to solve so far: While fiddling with the shoes Dan sent I noticed that two of the four linings are not applied evenly across the faces of their shoes, but asymmetrically offset a considerable distance more toward one end of the shoe. You can see it clearly in the images above and below. The other two are symmetrical, as one would expect. At first I thought this was some kind of oversight or mistake. Did the brake shoe re-liner guys run out of material? But then I noticed a similar arrangement in the image of the rear brake shoes in the factory repair manual. The image of the front brake liners shows they are evenly and symmetrically distributed across the face of their shoes but both rear liners are offset. There must be a reason for this but so far no one has come up with a definitive explanation.

Definitive explanations, scientific hypotheses, and wildass guesses are herewith invited . . . .

Drum brakes vs disc brakes

ReplyDeleteDunlop is credited with coming up with disc brakes in the early fifties notably in the winning D-type at LeMans in 1954 I believe. Think about the service requirement…very heavy braking from very high speed. Exactly what is required in aircraft landing. That was not exactly what the service requirement was in the average passenger car in the era under consideration. The disc brake had no “bite” and that is why they were not adopted. Gradually power brakes overcame that deficiency. But, note that was not many passenger cars retained drum rear brakes and event today some do.

The marked competitive prowess of Alfa’s in the 1900/Giulietta era were due to their superb brakes and Alfa was thus late in introducing discs until convinced the discs were better.

The remarkable 1900 drum brakes should work superbly well. But many users have problems. Of course the main aim was to reduce brake fade. Brake fade is brought on by heat and even the relatively huge finned drums were not enough for Alfa engineers who added cooling ducts on the fronts. Today a very small minority use the cars under brake fade conditions (read Stelvio pass) .The large dimensions of the drums and shoes demand a high degree of attention to detail in assembly but the adjustment mechanisms for the important fronts is relatively flimsy. There is a special tools for measuring lateral adjustment. Who has one? There is a small threaded nub in the backing plate for lateral adjustment that is easily worn down (or lost). The spiral shaped shoe adjuster is thin and usually worn out including the serrations. No doubt a replacement would have to be machined. Where is the pattern? I believe the installer needs to grind a gradual taper of the leading part of the shoe lining.

I think I have an explanation for the mystery about the uneven brake shoes on the rear brakes, shown in your post #128. You have a picture of the R rear brake from the factory manual. The rear brakes have only one brake cylinder so one shoe is “leading” and the other is “trailing”. The leading shoe is self-energizing, meaning the rotation of the drum (CW) tends to pull the shoe tighter, increasing the braking force. (That’s why the front brakes have two cylinders.) They made that shoe with the lining farther down the shoe so its force is more like the trailing shoe, thus equalizing the wear and applied force.

ReplyDeleteSound plausible?

Sounds very plausible to me. How can we verify it?

ReplyDelete

ReplyDeleteThanks for this informative article. It's really great.

jeep wrangler wreckers

buy jeep wrangler parts